Table of Contents

Introduction

Onions are one of the most widely grown and consumed crops in India, forming the backbone of household kitchens and farmer incomes alike. However, once harvested, onions are highly perishable and can quickly rot or sprout if not handled properly. This is where the process of curing becomes essential.

Curing is not just about drying onions; it is a simple yet powerful post-harvest step that extends shelf life, preserves quality, and reduces storage losses. For Indian farmers, who often face price fluctuations and storage challenges, proper curing can make the difference between profit and loss.

In this blog, we will explore what curing means, why it is important, the methods commonly practiced, and useful tips to help farmers get the best returns from their onion harvest.

So, without further delay, let’s dive into the blog.

What Does Curing Onions Mean?

Curing onions means drying the outer skin, neck, and roots of the harvested bulbs to remove excess moisture and prepare them for long-term storage. It is one of the most important post-harvest steps, especially for bulb onions that need to be stored or sold later in the season.

When onions are pulled or dug out from the field, the neck and outer layers still contain moisture. If stored without drying, this moisture can cause fungal infections, rotting, or sprouting. Curing helps seal the neck, dry the roots, and allows the outer skin to turn papery and protective.

In Indian conditions, onions are usually left under shade for around 4 days after harvesting. This helps them lose surface moisture gradually while being protected from harsh sunlight and rain. Once properly cured, onions can last for several months in storage without losing quality or weight.

Importance of Curing Onions

Curing is more than just drying onions; it acts as a protective shield that safeguards your harvest, ensuring longer storage life and better market returns.

Prevents Post-Harvest Losses from Disease

Moisture in the neck and outer scales creates a breeding ground for fungal and bacterial pathogens like neck rot, gray mold, black mold, and soft rot. Curing removes this moisture, sealing the bulb and preventing disease spread.

Reduces Weight and Quality Loss

Curing lowers onions’ respiration rate and moisture content, thereby reducing weight loss. Studies show that onions cured for 4 days in the field lost as little as 3–5%, compared with 50% loss in control groups. This means more sellable bulbs and higher net income.

Improves Market Appearance and Shelf Life

Curing promotes a tight, papery outer skin and a shriveled neck, giving onions a clean, bright look that attracts better prices. Properly cured onions can last comparatively longer in storage with minimal sprouting or decay.

Enables Controlled, Year-Round Supply

In India, onions are harvested in different seasons and need to be stored during off-season months. Proper curing and regular monitoring can help farmers maintain a steady supply, sell when prices are high, and reduce the impact of price fluctuations.

When and How to Start Curing Onions

When to Start Curing Onions

Curing can begin immediately after harvesting, but only when the onions have reached the right stage of maturity. For bulb onions, maturity usually occurs about 4 months after planting, depending on the variety.

You can identify maturity through the following signs:

- The tops begin to bend or fall just above the bulb.

- The leaves are still green, not fully dried.

- The outer scales (skin) become loose and colored.

How to Start Curing Onions

- Do not wash the onions after harvest, as moisture can increase the risk of rot.

- Gently shake off loose soil or remove it by hand to avoid wet cleaning.

- Spread the bulbs in a single layer, keeping the necks upright.

- Keep onions under a well-ventilated shade or roof, not in direct sunlight.

- Ensure good air movement around the bulbs. Use bamboo racks, nets, or slatted platforms if possible.

- Avoid piling the onions for the first few days, as this traps moisture.

- Allow curing to continue for about 4 days in warm, dry weather.

- Cut the tops and roots only after the neck is fully dry and tight.

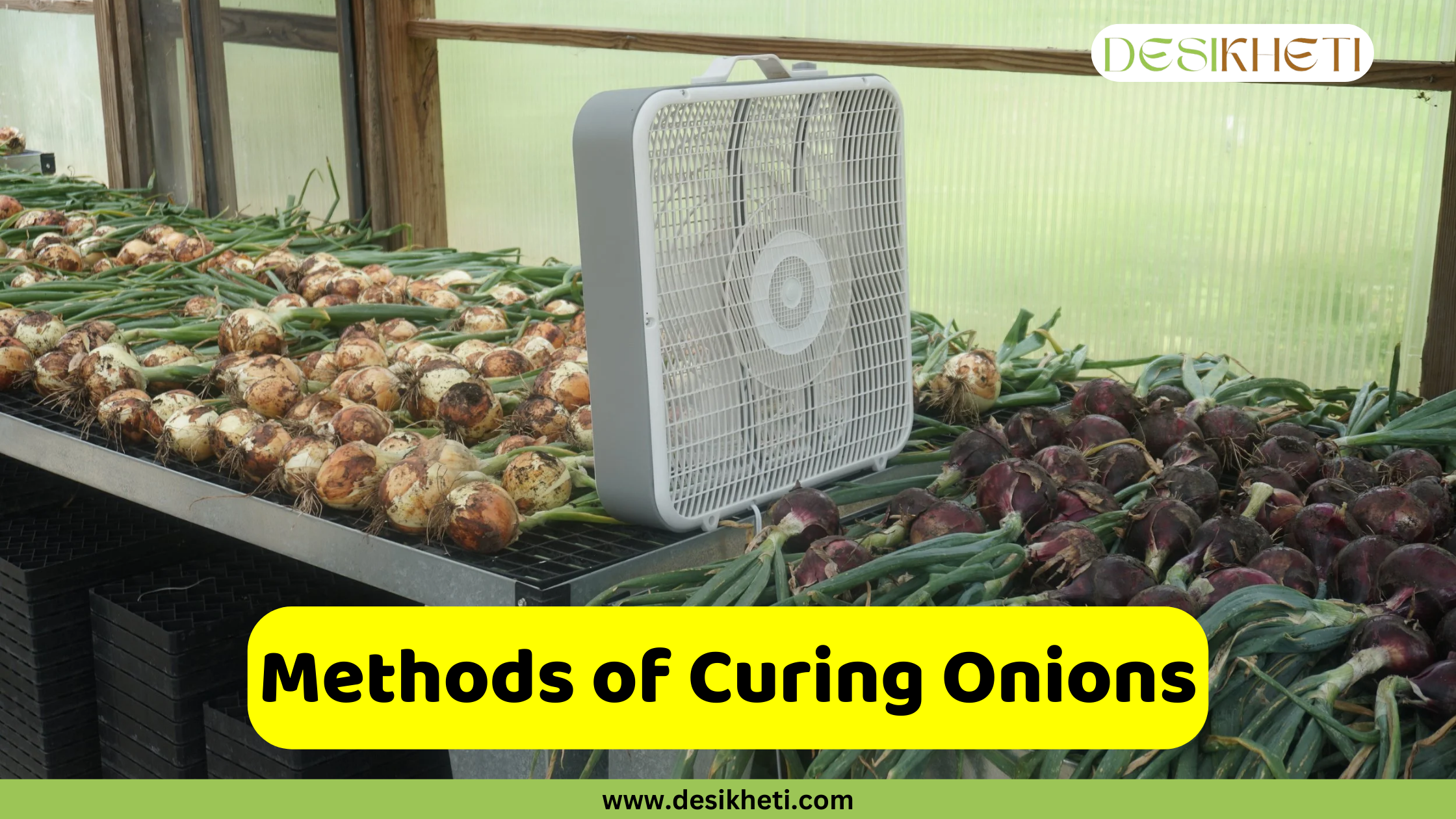

Methods of Curing Onions

There are different methods of curing onions. We have discussed a few methods used by farmers in this blog, ranging from simple field curing to advanced forced-air systems, each offering effective ways to dry onions properly:

1. Field (Natural) Curing of Onions

After harvest, onions are laid in windrows or small heaps in the field, often with tops left on or used as shade cover.

- Typically takes 5–15 days, depending on weather. Warmer and drier conditions allow faster curing.

- Best suited for dry-season climates. But rain, unexpected moisture, or storms can slow the process or spoil bulbs.

Pros: Very low cost; uses natural climate.

Cons: Weather-dependent; risk of sunburn or rot; uneven drying.

2. Shade or Shed Curing of Onions

Onions are spread in single layers on mats, racks, trays, or crates in a well-ventilated shed or shaded area.

- Often combined with shade cloth or branch covers to prevent sunburn.

- Requires 10–20 days in dry shade.

Pros: More uniform drying.

Cons: Requires space and labor; slower than forced-air curing.

3. Artificial or Forced-Air Curing of Onions

Onions are stacked in bulk on slatted floors or bins while warm, dry air is blown through at 70–115 °F (21–46 °C) and 20–75% RH, depending on whether they are wet or dry.

- Drying usually takes 1–2 days when done correctly but can extend up to 14 days depending on temperature, moisture, quality of bulbs, and other factors.

- Careful monitoring is needed to prevent over-drying or softening of bulbs.

- Pros: Fast, uniform results; applicable year-round.

- Cons: Higher setup cost; requires power and maintenance.

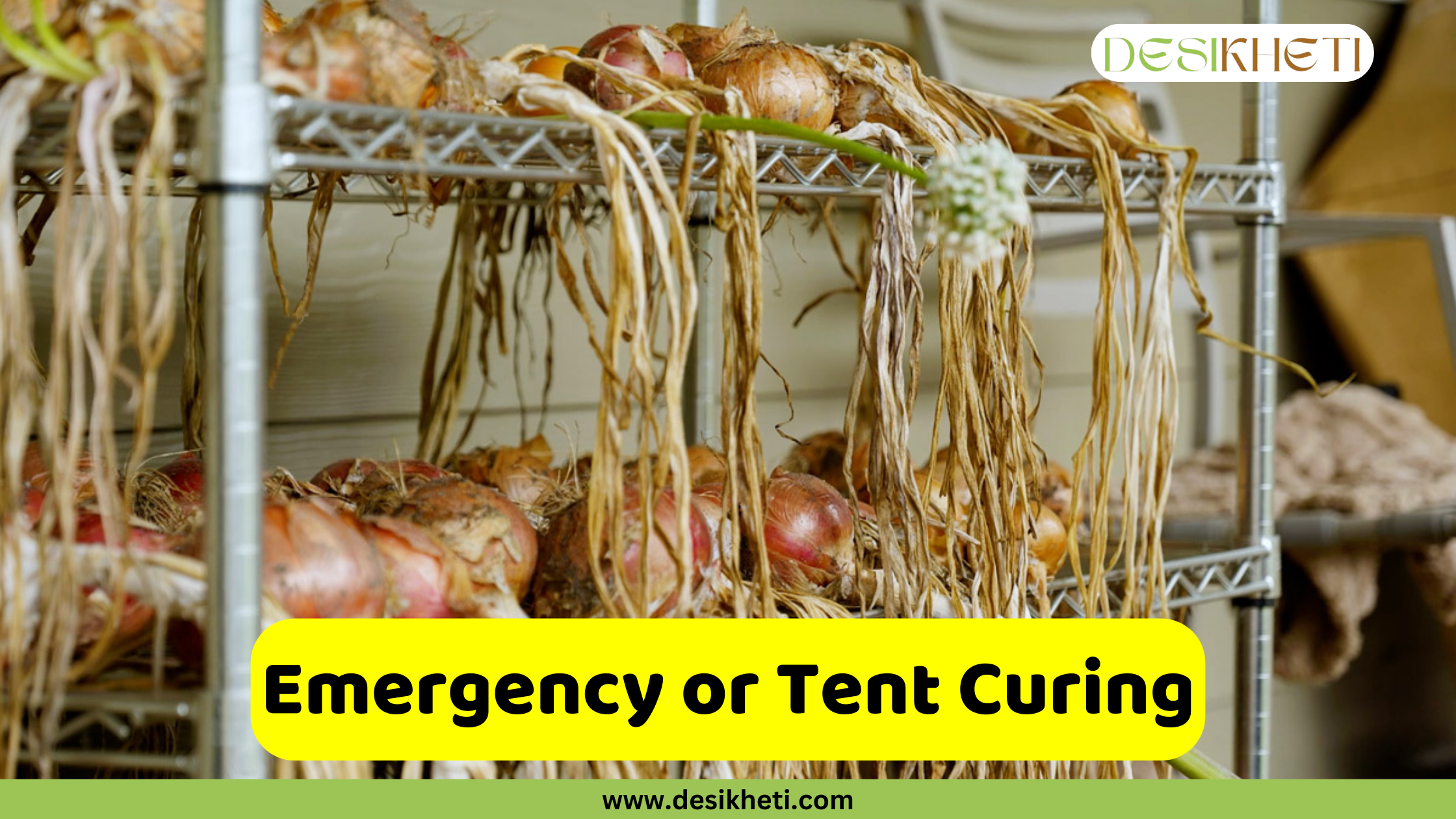

4. Emergency or Tent Curing of Onions

This method is useful when unexpected rain affects freshly dug onions.

- A temporary shade or tent is made with tarpaulin, and fans are used to circulate warm air.

- Pros: Quick, low-cost solution.

- Cons: Requires manual setup and temporary space.

How to Tell When Curing Is Complete

It is important to know when curing is complete so that onions can be safely moved to storage or the market. Both over-curing and under-curing can affect quality and shelf life. Here are the main signs to check:

1. Dry Outer Skin (Scales): The outer layers of the bulb should be papery, dry, and rustle when touched. The skin also becomes firm and develops a bright color depending on the variety (red, white, or yellow).

2. Tight and Dry Neck: The neck (where the leaves meet the bulb) should be completely dry, thin, and sealed. If the neck is still moist or thick, the bulb may rot during storage.

3. Brittle Roots: The roots of a cured onion become dry, shriveled, and break easily when touched.

4. Firm Bulbs: When squeezed gently, the bulbs should feel hard and solid, not soft or spongy.

Once these signs are visible, the curing process is complete. You can trim the dried tops to about 2–3 cm, remove loose outer skins if needed, and prepare the onions for storage or sale.

Common Mistakes to Avoid During Curing

Even minor mistakes in curing can significantly increase onion losses. Here are some frequent mistakes and how to avoid them:

1. Washing Onions After Harvest: Do not wash onions before curing. Added moisture increases the risk of fungal infections during drying and storage.

2. Piling Them Too Soon: Stacking fresh bulbs traps moisture and blocks airflow, creating ideal conditions for rot and mold.

3. Cutting Tops Before Necks Dry: Removing tops early, before the neck is fully dry, opens a pathway for bacteria and fungi such as neck rot. Many growers recommend leaving green tops during drying.

4. Exposure to Direct Sunlight or Rain: Overexposure to the sun can cause sunscald and soften bulbs, while rain or high humidity delays drying and encourages disease.

5. Curing in High Humidity Conditions: High humidity drastically slows drying and increases the risk of rot.

6. Using Poor Ventilation and Tight Storage: Placing onions in sealed sacks or poorly ventilated areas traps moisture, leading to sprouting or mold. Instead, use mesh bags, crates, or ventilated racks.

7. Neglecting to Sort Damaged Bulbs: Leaving bruised, sprouted, or cracked onions in the batch allows disease to spread to healthy bulbs. Always remove damaged onions before storage.

Storage of Onions After Curing

After your onions are fully cured, storing them correctly is crucial for maintaining quality and extending shelf life.

Ideal Storage Conditions

- Temperature: Aim for 0–5 °C (32–41 °F) in cold storage for long-term preservation, or 25–30 °C (77–86 °F) under ambient conditions.

- Humidity: Maintain 65–70% RH to prevent both shriveling and mold.

- Ventilation: Provide good airflow using ventilated crates, mesh bags, or open bins. Avoid sealed sacks.

- Light & Ethylene: Store in a cool, dark place, away from sunlight and ethylene-producing items such as potatoes and apples, as they can trigger sprouting.

Recommended Storage Structures

- Ventilated Sheds/Godowns

- Elevated floors or pallets help prevent moisture seepage.

- Provide cross-ventilation and shade ideal for rural farm settings.

- Traditional Slatted Systems

- Bamboo or wooden slats allow airflow from all sides.

- Effective and low-cost for Indian farming contexts.

- Mesh Bags, Crates, or Hanging Baskets

- Onions can be hung (braided or tied) or stored loose in baskets, ensuring ventilation.

C. Monitoring & Maintenance

- Inspect weekly for sprouting or rotting bulbs and remove them immediately.

- Sort damaged bulbs before storage to prevent contamination of healthy ones.

- Avoid placing onions near moisture-rich crops, especially potatoes and apples, to reduce spoilage.

- Ensure regular airflow; turn stored onions occasionally or use vents to keep them fresh.

D. Expected Storage Duration

- In ambient storage under recommended conditions, onions can last 3–6 months in tropical climates.

- In cold storage, their shelf life can extend to 6–8 months.

Curing is a vital step in onion farming that ensures Onions lasts longer, fetches better market prices, and reduces the risk of storage losses. Whether you use natural field curing, shaded shed drying, or advanced forced-air methods, the key is to make sure onions are fully dried, with papery skins and tight necks before storage.

For Indian farmers, investing a little extra time and care in curing can result in higher income, a steady supply, and greater resilience against post-harvest spoilage.

FAQs on Curing in Onions

1. What does curing onions mean?

A. Curing onions means drying them after harvest to remove excess moisture, allowing the outer skin and neck to harden for better storage..

2. Why are onions cured?

A. Onions are cured to extend shelf life, prevent rotting, and maintain quality during storage and transport.

3. What are the benefits of curing onions?

A. Curing reduces moisture content, prevents fungal infections, improves storability, and enhances flavor.

4. How do you know when onions are cured?

A. Onions are fully cured when the necks are tight and dry, and the outer skins are papery.

5. How long do cured onions last?

A. Properly cured onions can last 3–6 months in dry storage.

6. What is the difference between fresh and cured onions?

A. Fresh onions are high in moisture and have green tops, while cured onions have dry necks and papery skins suitable for storage.

7. Do onions need to be cured before storage?

A. Curing is essential for long-term storage to reduce spoilage and extend shelf life.

8. Why do onions rot in storage?

A. Rot may occur due to excess moisture, poor curing, improper ventilation, or fungal and bacterial infections, etc.